Introduction:

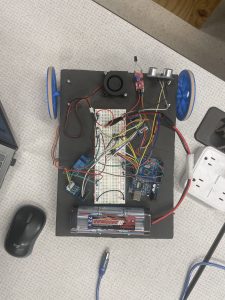

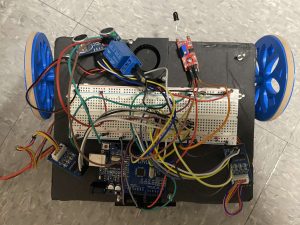

Our final project was all about making a robot that can navigate mazes, find fires, and put them out. The robot had 3D-printed mount motors on a foam board, two custom wheels for the robot, and a third ping-pong ball wheel. To understand more about our robot and what our teachers wanted, take a look at my previous posts on [Motor Mount] and [Sensor Setup].

Our Approach:

For this challenge, we carefully devised a step-by-step plan to tackle the maze-solving and firefighting tasks. We strategically integrated various sensors into our robot’s design, ensuring it could efficiently navigate through the maze. One key aspect was creating a robust maze-solving algorithm, which involved learning from our homework assignments and gradually building the necessary skills. Additionally, we implemented a smart mechanism for fire detection and devised a solution to extinguish the flames effectively.

We started by understanding the capabilities of each sensor, such as the ultrasonic sensor for distance measurement and the flame sensor for fire detection. Building on this foundation, we formulated a comprehensive maze-solving plan, incorporating turning maneuvers and forward movements guided by sensor inputs.

To address the firefighting aspect, we designed a mechanism that could identify the presence of a flame and respond promptly. This involved integrating a relay for controlling a fan to suppress the fire. Our approach was not just about creating a robot that could move in a maze but also ensuring it could fulfill the firefighting objective with precision.

This planning and integration of sensors laid the groundwork for a well-rounded robot capable of navigating mazes and responding effectively to fires. For a more detailed explanation of our maze-solving algorithm, feel free to explore my partner’s insights in their dedicated blog post on Zachary Williams.

Design Changes:

At first, we wanted our robot to look like a fire truck with cool lights and a siren sound. But, because of time and material limits, we decided to keep it simple and focus on making the robot work.

Our first robot design was too long, and the foam board started bending because it was too heavy. So, we cut it in half and used the extra piece to make a case for the battery under the foam board. This fixed the bending problem and also gave us a good solution for storing the battery. Even though our robot looks different from our first idea, these changes helped make it work better, showing how we adapted to challenges during the design process.

Exploring Programming:

The journey of programming our robot was both challenging and exciting. We utilized libraries and crafted our own set of functions to make the robot follow our commands effectively. To better understand our programming logic, we created a visual representation in the form of a flowchart, providing a roadmap for the robot’s actions.

Recent Comments