Project: Hubs and Wheels

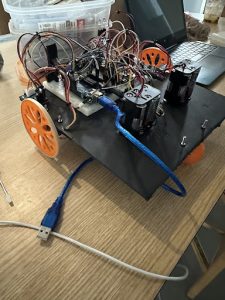

This project was made mainly in Creo Parametric, with my partner on the Fire Fighting Robot.

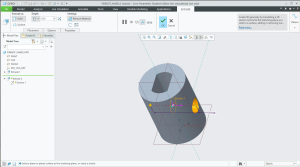

We measured the Double D shafts on the stepper motors, and after that, we translated that size to a Hub that we printed, and the hub fit perfectly. We also installed a set screw hole in the mount that allowed for a 3 mm screw to go in.

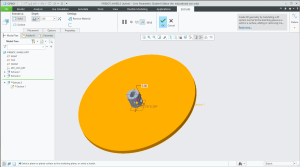

Once our hub fit, we went back to Creo and designed a wheel around the same Hub. We made the wheel so that the robot would have a slight lift to it. This was so the Sensor would not be prone to looking at the ground but slightly at an upward angle.

.

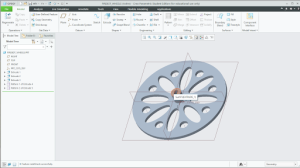

Once we merged the wheel circle and the hub, we began carving away at the wheel material to reduce the wheel weight and allow for shorter print times. Once we got the wheel done, we printed the hub and wheel, and both wheels took a took total of 4 hours to print. Once we got the wheels printed, we attached them to the robot and put the set screws. When we started testing the robot, a traction issue appeared that was fixed by putting rubber bands around the edge of the wheel.

Recent Comments