The Bouncy Ball Mini Project was a sub part of a larger project for my ENGR 200 course during spring 2024. In this project we had to a bouncy ball move from the starting point which was the end of a large OSB board to a pit in the middle of the board. During this project me and partner could only touch the ball when putting it in the mechanism to get the ball to the desired destination. For this project me and partner decided to use some parts from the larger project in order to create a ramp would be long enough to roll the ball from the starting point to the end point, this designed we hoped would be able to overcone all obsticals that the professor could throw at us.

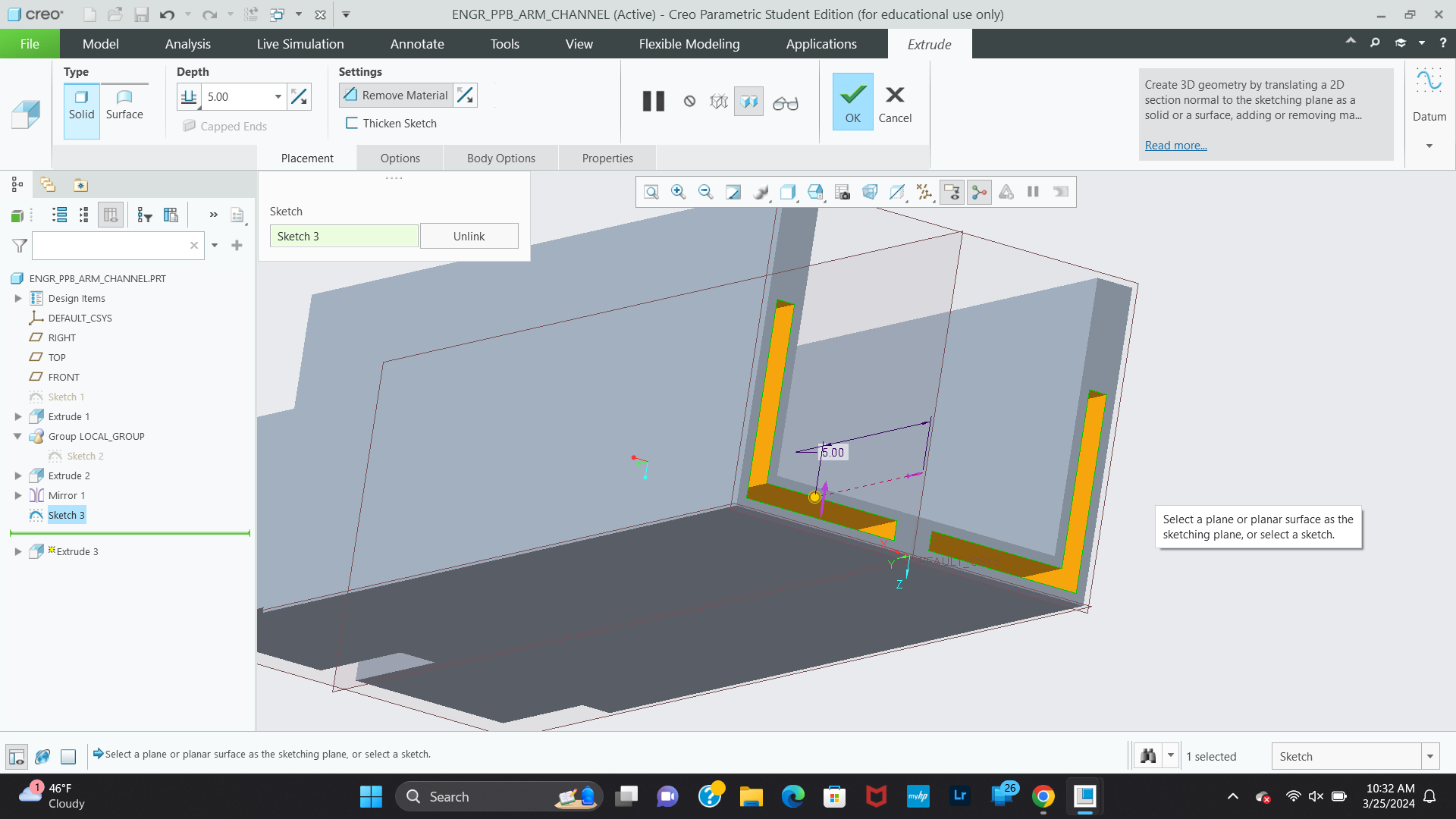

The main part of this project were a series of C channels that were stuck together with one end elavated to angle, so the ball would roll down and land in the pit.

Other Design Ideas

In this project we came up with a few different designes to accomplish the goal of the project. One of these designs was a bow system that would launch the ball into the pit, we decided to scrap this design due to the fact that it would be hard to control the power of the bow, as well as the accuracy, the number of obsticales would also hinder the effectivness of this design. Another design we came up with was a ramp that would just roll the ball, but this design would be hindered by the introducion of any obstacle that was touching the surface of the board. For the final design we used a version of the second design, with walls designed to control the direction the ball rolls, to give us a level of accracy. When in the process of desgining this ramp, we realized that if we use the parts we have already designed for the larger project, we could make a long enough ramp to go from the start to the end pit, this is the design we chose to go with.

Final Test Results

During the final test of this design we overcame every challange but one that could be created. Some of these challanges consisted of an angled table, to make the ball go up hill, and down hill. Other challanges included covering the pit with books and lids to make a gap that a ball could barly get through. The only challange that stopped our design was when a set of lids prevented the ball from bouncing into a hole that further int the stack of books and lids.

Figure 1: Front end of the C-Channel in Creo Parametric

Figure 2: Back end of the C-Channel in Creo Parametric

Figure 3: Completed Ramp, with all C-Channels attached.

Recent Comments