In this project, I created a Keychain attachment with the name “Ashe” on it. I had to use Computer Aided Design programs (CAD) to produce this keychain to the specifics required so that is both durable and fits any keychain.

In this project, I used an Arduino Uno to create a pattern of lights that fade on and off. In short, I created a program for Christmas lights.

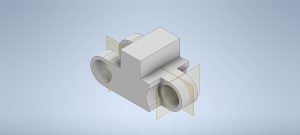

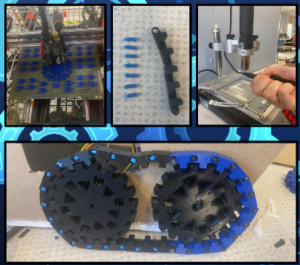

Robot Motor Mount

In this project, I created a L bracket in Inventor that I can use to hold my motor for my future robot’s wheels (or gears if I can figure out how to make the tank links that fit into the gears properly). The piece was printed with PLA plastic, with a 15% infill (the standard amount), and the design was created in class as an example for a different design, so more likely than not the final design will not include this piece.

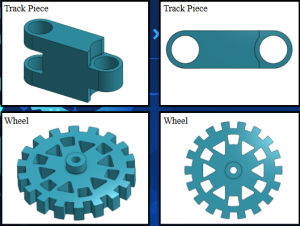

(Unfortunately, the assembly file was lost, but the gears are larger than the tracks, causing the tracks to get stuck on the gear)

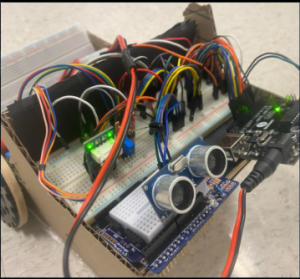

In this project, I created a contraption that takes ultrasonic readings and uses the inputs to control a Servo motor. These kinds of motors and electronics are used in grocery stores, convience stores, and home goods stores where the doors open and close automatically.

Fire Fighting Robot

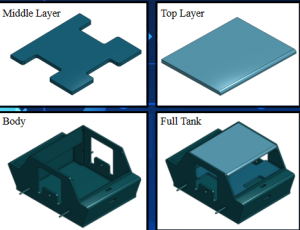

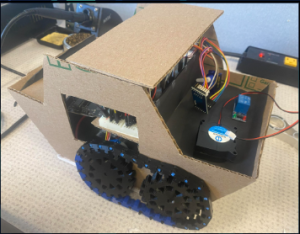

This project was the final project for ENGR 199; requiring skills with CAD software, electrical components and wiring, as well as critical thinking and problem solving. The goal of this project was to navigate a maze and extinguish the flame at the end of the maze. My partner Kat (Linked here) and I designed a tank that has gears and tracks that I hand created with AUTODESK Inventor, and the chassis that Kat created using Onshape.

Unfortunately, our project was not successful. The entire robot was too heavy at first, then the tracks repeatedly slipped off the gears, and once we finally got the robot to start moving properly, one of the gear hubs completely melted. Theoretically, we would have printed another one, but due to delayed testing, we lacked the time and access to print a replacement.

In the future, my partner and I agreed that we should have started earlier. Besides that, I would change the way that the treads were printed. I used PLA to 3d print each track, which then had to be linked together. That process alone took upwards of 8 hours of assembling, and 16 hours of printing. I learned about a different material called TPU, which is flexible, elastic, and could have been printed all at once. This simple conversion to a different material could have saved hours of work that we could have spent on testing, not to also mention that TPU is much lighter and has better traction than the PLA does.

Recent Comments