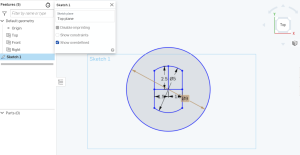

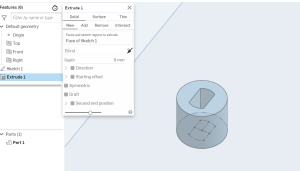

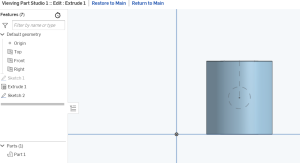

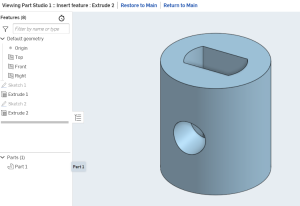

I went on Onshape, started in the top plane, and created the sketch of the motor hub with the dimensions below. I made a small circle, put two lines close to the circle’s edge, and removed the spare parts to make the part that goes over the stepper motor. Then I made a second circle to go around. The 1st one hub would stay on the stepper motor. The last thing I did was extrude the hub. After that, I went to the right plane to make the 3 mm holes on each side of the hub, starting with a straight line down the middle on that side and drawing a circle with a diameter of 3mm, and readjusted the initial extrusion by 2 mm. I then made a second extrusion for the 3mm hole to come out on both sides of the hub.

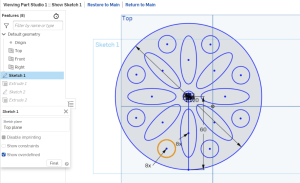

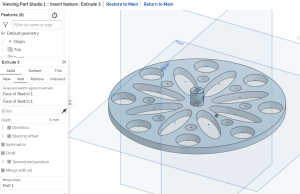

When it came to the wheel, I used the exact measurement my partner used for their wheel, which was for the wheel to be 120mm in diameter and 5 mm thick. I also put shapes on my wheel to make it look nice by adding ellipses and small circles to give it a flower shape. To add the ellipses and the smaller circles, I made a straight line from the center of the circle to get a radius of 60mm, and on the same line, I made the first ellipse the center of the said ellipse would be on the line. I then clicked the pattern tab and played around until I 8 even spaced ellipses. And I did the same thing with the circles starting with the bigger one between every ellipse, so there were 8. I kept readjusting the diameter of the circles to make them look presentable in the end. Each bigger circle had a diameter of about 12 mm, with the eight smaller ones having a diameter of 6mm before lastly extruding the wheel and the bottom of the hub so that they were connected to be 5 mm.

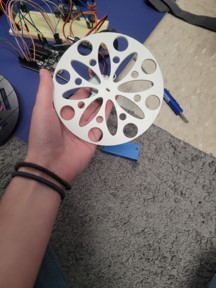

This was the result after 3D printing it with a Prusa mini.

Recent Comments