For the robot I am building for the conclusion of the my Engineering 199 class, wheel were required. This page documents the steps from the realization of need to the creation of the part.

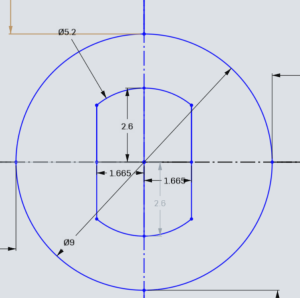

The wheel hub was designed first. This was done to limit plastic waste from 3D printing while attempting to make the correct fit.The image here has dimensions slightly larger than that of the corresponding part of the stepper motor to account for the expansion of the plastic when it has finished printing. These were the final dimensions. Though it cannot be seen in this image, the set screw hole for the hub was set to 2.99 mm to ensure the screw could be comfortably slotted into the hole but would also be tight enough to not back out.

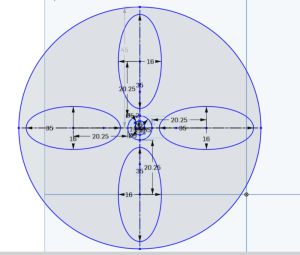

Immediately following the creation of a well fitting wheel hub, the entire wheel was printed to limit differences between the hub and its wheel. The gaps within the wheel were done with the intention of the limiting the amount of plastic used and increasing the speed with which it could be printed.A wheel of radius 45 mm and a thickness of 2mm were decided upon as the final iteration.

The following image shows the attempts of printing parts of the correct size; from the first attempt on the left to the wheels being used on the robot on the right.

Recent Comments