This blog will be going over my Tiny House project for one of my projects done for the Academy of Engineering at Southern Lee High School, date being Dec 9, 2020 I had already designed this project on the school desktop earlier in the year since this was a year long project which was thought from the engineering of our first year in highschool to second and where required to get certified in autocad before being given the project overview.

Tiny House

The primary objective of my project was to design a fully functional home within the limited space of a shipping container. To achieve this, I needed to consider space-saving solutions while ensuring the home had all the necessary components of comfortable living. My specific goals included:

- Converting a shipping container into a 520-square-foot livable home.

- Achieving at least two LEED Certifications to make the home energy-efficient and environmentally friendly.

- Designing a compact but fully functional living space that includes a bedroom, kitchen, bathroom, storage area, and living room.

Designing Without CAD: A Major Hurdle

Before the pandemic, AutoCAD was my primary tool for engineering design, and I was already certified in using it. I had initially created the digital model for my tiny house on my school laptop, but once remote learning began, I no longer had access to the necessary software. My laptop did not support AutoCAD or any other CAD program, forcing me to rethink my approach to modeling.

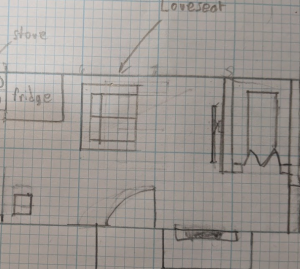

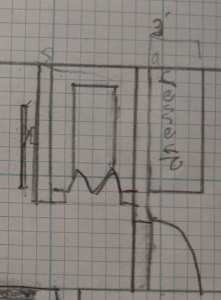

Determined to continue, I resorted to hand-drawing my designs using a ruler, pencil, and grid paper. This process was time-consuming and required careful attention to detail, but it allowed me to translate my ideas onto paper in a structured manner. Though I missed the precision and efficiency of digital tools, this challenge reinforced my ability to work with traditional drafting methods—an essential skill for any engineer while also making a smaller scaled version of my project to show the class.

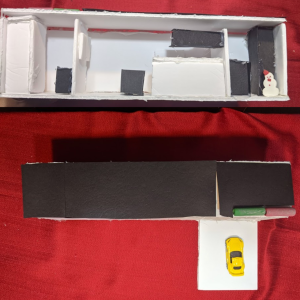

Building the Model at Home

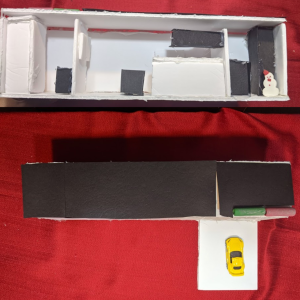

With my hand-drawn blueprints as a guide, I proceeded to construct a physical scale model using readily available materials. These included white cardboard, black hard sheet paper, a hot glue gun, and even a Hot Wheels Honda S2000. The process required creativity and problem-solving, as I had to ensure all necessary components—such as a bed, storage area, kitchen, bathroom, and living space—fit within the limited dimensions of the tiny house.

- Before constructing the model, I brainstormed the essential features my tiny house needed. Given the limited space, I had to find creative ways to integrate a:

- Bedroom with a workspace and storage.

- Kitchen equipped with necessary appliances.

- Bathroom that includes a step-in shower, toilet, and sink.

- Storage space that maximizes available room.

- Living area that allows for comfort without taking up too much space.

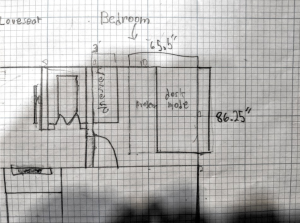

Bedroom Design

The bedroom was one of the most challenging areas to design because it needed to be compact yet functional. To maximize space, I incorporated a Murphy bed, which folds into the wall when not in use. This allowed for additional workspace during the day. A standard dresser provided necessary storage, and I ensured there was enough room for an office or study area within the same space. The compact layout was designed to ensure efficiency without compromising comfort.

Bathroom Layout

For the bathroom, I included a step-in shower, a toilet, and two sinks to accommodate potential users. The placement of these elements was carefully planned to ensure the bathroom remained accessible without taking up too much room. The double sinks were an added convenience, optimizing usability in a small area.

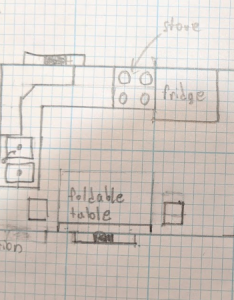

Kitchen Design

Kitchen Design

The kitchen followed an L-shaped layout, which provided ample counter space while allowing for movement within the compact area. The kitchen featured:

- A sink positioned for easy access.

- A stove and microwave for essential cooking needs.

- A full-sized refrigerator to ensure enough food storage.

- A foldable dining table designed for two but expandable to fit three people when necessary.

The foldable table was one of my primary space-saving strategies, allowing for flexibility depending on the number of occupants at any given time.

Living Room Setup

The living room needed to be comfortable while taking up minimal space. I opted for a loveseat instead of a full-sized couch and positioned a wall-mounted TV to free up additional room. The goal was to create a cozy but uncluttered space where one could relax without feeling cramped.

Storage Solutions

Storage Solutions

Since space was limited, I strategically designed a storage area near the bedroom. This space measured 3 feet wide and 4 feet 6 inches long, providing a compact but efficient solution for storing household items. The foldable doors added flexibility and helped maintain an open feel within the tiny house.

Sustainable Features and LEED Certification

One of the key aspects of my project was sustainability. To meet LEED certification standards and cut down on utility costs, I incorporated several eco-friendly features. Solar-paneled roof: Provided clean, renewable energy. Stormwater collection system: Used a sump pump to recycle water, reducing overall water consumption. Solar water heater: Helped lower emissions and cut energy costs compared to traditional water heating systems. Powerwall battery system: Allowed stored solar energy to power the home, reducing reliance on the electrical grid. These features ensured that my tiny house was not only compact and functional but also environmentally responsible.

Materials Used

Building my model required various materials, including:

- Ruler and pencil for precise measurements and hand-drawn blueprints.

- White cardboard and black hardsheet paper to construct the walls and roof.

- Hot glue gun for assembling the structure.

- Pencil grips and small-scale items to represent furniture.

- Hot Wheels Honda S2000 to provide a size reference for the model.

Model Construction

Model Construction

After finalizing my blueprint, I began constructing my scale model. The process required careful cutting and assembly, ensuring that each component fit within the intended layout. I built separate sections for each room, following my hand-drawn plans to guide placement and proportions.

Challenges Faced

Challenges Faced

Working on this project outside of a classroom setting presented several difficulties:

- Scaling issues: Without access to digital tools, I found it challenging to scale my model accurately, which affected how the interior elements fit together.

- Limited materials: Since I was at home, I had to be resourceful with materials, leading to compromises in the model’s structural precision.

- Technical difficulties: My hot glue gun malfunctioned, making clean assembly difficult and causing unwanted glue residue.

Lessons Learned

Despite the challenges, I gained valuable insights, including:

- How to manually scale and draft blueprints without digital tools.

- The importance of maximizing small spaces through smart design.

- How to improvise and adapt when facing constraints in resources and technology.

Reflection and Conclusion

As a freshman in high school, this project gave me my first real insight into the engineering design process and the importance of adaptability. While I had prior experience with CAD, the limitations imposed by remote learning forced me to rely on fundamental engineering principles, like manual drafting, spatial planning, and model construction.

Through this experience, I learned how to problem-solve creatively, how to optimize space efficiently, and how to apply sustainability principles in a real-world scenario. It also gave me a hands-on understanding of how engineers must work with constraints, whether they be software limitations, material availability, or design challenges.

Looking back, I realize how foundational this project was in shaping my engineering approach. It taught me that engineering is not just about using high-end software but about thinking critically, innovating solutions, and adapting to the resources available. The ability to pivot and find alternative methods to complete a project is a crucial skill in engineering, and this early experience helped me develop it.

As I now pursue more complex engineering projects and continue advancing my skills in mechanical design, this tiny house project remains an important milestone. It serves as a testament to my resilience, creativity, and drive to find solutions even in challenging situations—qualities that I bring into every engineering endeavor I undertake.